Food Processing Equipment

Contact Us: Sales@ScansteelUSA.com

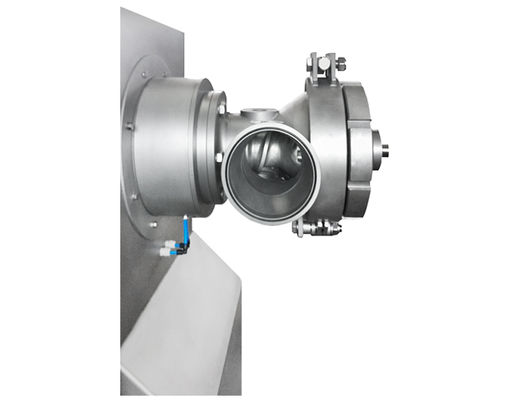

Emulsifier

Heavy Duty MC 300

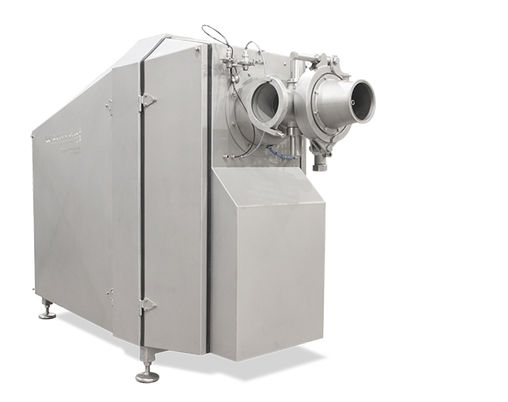

EMULSIFIER: Heavy Duty MC 300

The Industry “Work Horse” Emulsifier Does It All!

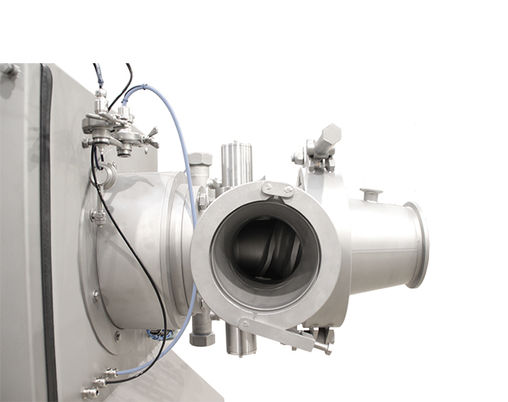

The MC 300 emulsifiers have a unique dual feeding/two steps feeding system:

• Stand-alone feeding pump, feeding the lining/housing of the MC 300.

• Feeding/crushing screw, feeding the knife set.

The feeding pump with its own feeding screw with block breaking/bone breaking abilities force-feeds the MC 300 emulsifier lining/housing. Entering the lining/housing, the feeding screw of the MC 300 further force-feeds/grinds any particles, being frozen meat raw materials and/or bones. The feeding screw with its recessed 3-bladed knife distributes any products continuously towards the first hole plate securing optimal cutting/emulsifying effect.

Designed To Emulsify/Particle Reduce, Examples Only, Products Such As:

• Pre-broken frozen meat raw material blocks.

• Fresh meat raw material.

• Chicken bones, pork bones, beef bones.

• Frozen and fresh combination of above.

Direct Steam Injection System:

Heavy Duty steam valves connected directly in-line in the lining/feeding screw

to secure even distribution of steam and subsequently final temperature.

Knife Set:

The MC 300 emulsifiers can be equipped with single, double, or triple knife set. Controllable emulsifying effect with more/less hole plates:

1 hole plate = 1 (one) cutting edge against hole plate.

2 hole plates = 3 (three) cutting edges against hole plates.

3 hole plates = 5 (five) cutting edges against hole plates. With the wide selection of knives and hole plates, the scansteel foodtech MC 300 emulsifiers ensure you get the final emulsion/final product quality you require.

Technical Specifications

Model: MC 300

Capacity (approx.)

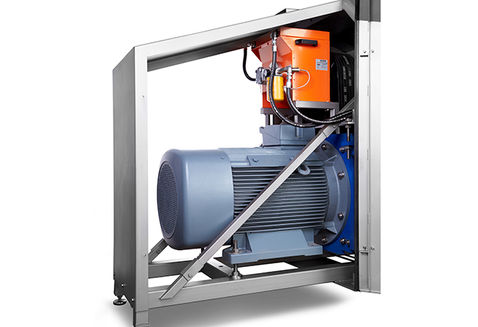

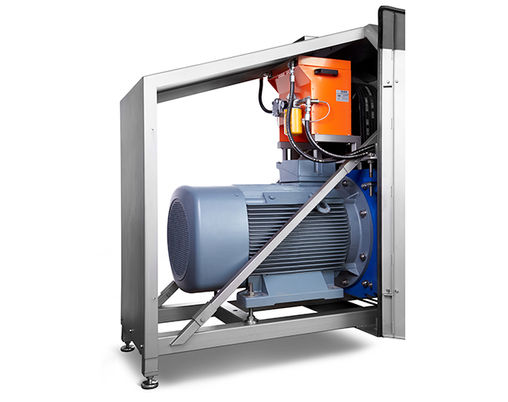

Power Motor:

Length:

Width:

Height:

Weight:

4000 – 12,000 kg/hour

90-200 kW

2300 mm

1000 mm

1700 mm

1,500 kg